Inventors: V.C. Li and S. Wang

US Patent No. 7,169,224

Issued on January 30, 2007

Performance Targets:

- Saturated Multiple Cracking and High Ductility / Strain Hardening

- Maintain material properties (ultimate tensile and compressive strengths)

Applications:

- Durability applications requiring high ductility, e.g. bridge decks, pavements, etc.

Suggested Key Words: ECC, Artificial Flaws, Saturated Multiple Cracking, Ductility, Matrix Tailoring

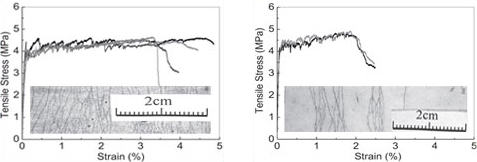

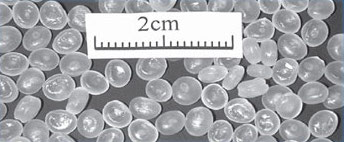

Non-Proprietary Description: Strain-hardening and magnitude of ductility in high-performance fiber reinforced composites are closely related to matrix properties, e.g. the pre-existing flaw size distribution and the matrix-fracture toughness. For a brittle matrix composite such as ECC, cracking strength is determined by the largest flaw in the section normal to the maximum principle stress. The maximum fiber bridging stress imposes a lower bound of critical flaw size such that only those flaws larger (han this critical size can be activated and contribute to multiple cracking. Insufficient number of large flaws in the matrix causes unsaturated multiple cracking. A practical approach to controlling the pre-existing flaws, i.e. introducing artificial flaws with prescribed size distribution, is presented in this invention. This approach was verified in two versions of PVA – ECC where multiple cracking is hindered by high matrix toughness. Direct uniaxial tension test results confirmed the validity of the proposed material tailoring approach. For more, read Wang & Li, 2004.