Inventors: V.C. Li and J. Kong

US Patent No. 6,809,131

Issued on October 26, 2004

Performance Targets:

- Flowable fresh mix

- Self-compacting

- Maintain material properties (strain hardening, multiple cracking)

Suggested Key Words: ECC, Self-compactibility, fiber, matrix, cement, ductility, composites

Non-Proprietary Description: Engineered cementitious composite, ECC hereafter, are cement-based materials incorporating discontinuous fibers as reinforcement. ECCs have superior ductility (about 500 times of the ductility of normal concrete in tension) developed based on ECC theory at the University of Michigan. Conventional concrete or cement materials are brittle and fail in a catastrophic manner when subjected to tensile loading. By introducing reinforcing fibers, however, one may alter the mechanical property of the cement material into quasi-brittle or ductile behavior depending on the mix proportion of the cement material and the type and amount of fiber used. The ECC theory indicates that a high ductility and high toughness cementitious composite can be realized with ordinary cement and a small amount of short fibers by properly selecting the material parameters involved. It has been proven that the fracture toughness of ECC can achieve as high as that of aluminum alloy. Furthermore, a conventional mix-and-cast process is still applicable for ECC as it uses only short fibers.

The super ductility and high toughness performance allow ECC materials to be used in demanding structures where severe loading or high deformation is imposed, such as in constructed facilities subjected to seismic loads. ECCs are being investigated as materials for enhancing durability and safety of building, civil engineering structures, and manufactured elements (e.g. pressure pipes).

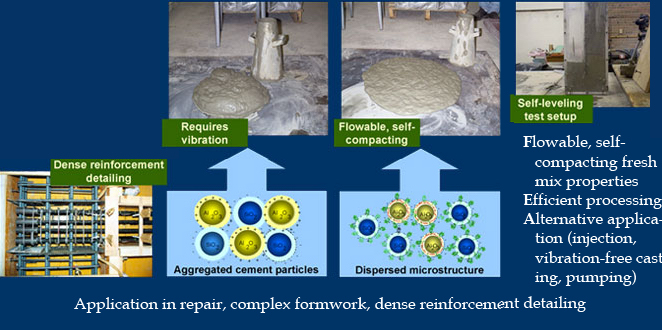

The self-compactibility of concrete or cementitious material refers to the capability that the materials can flow under its own weight and fill in the formwork in cast processing without external vibration. The self-compacting ECC refers to the ECC that possesses self-compactibility. Despite the presence of fibers in the compositions, the self-compacting ECC is able to overcome the obstacle of rebars and fill in each corner of the formwork easily without the aid of any external vibration.

Due to the sticky and inhomogeneous nature of concrete, the placing and casting of concrete in the field generally require sufficient vibration and consolidation. On the other hand, if concrete is not properly compacted or it is in lack of skillful workmanship, there can be gaps, voids, or cracks formed in the structure and the performance of the RC structure may be significantly influenced. A proper concreting process is, in fact, the most important factor to ensure the quality of construction of an RC structure. However, there are cases, such as formworks with complicated and congesting reinforcement or those with unusual geometries, that the vibration and consolidation are difficult or even impossible to be conducted. If concrete can be made self-compacting, the vibration and consolidation may, therefore, be eliminated and the quality of construction can still be ensured.

Apart from reliability and constructability, advantages such as the elimination of noise level in processing plants (such as pre-cast plants), and the reduction of construction time and labor cost have been cited as arising from the self-consolidation function of self-consolidating concrete.

Self-compacting ECC is a new material which combines all the advantages of both super ductility performance in the hardened state and self-consolidation function in the fresh state.

The self-compacting ECC is made possible due to the techniques of mix proportioning and chemical admixtures. The technique of mix proportion of cementitious matrix controls the extent of particle contact and interaction to minimize the friction between the solid particles. The technique of chemical admixtures adjusts the physicochemical properties of the mix of fiber and cement matrix resulting in optimal dispersion and viscosity of the mix. The self-compacting ECC has been designed in such a way that the mix of fiber and matrix can easily deform under its own weight and, at the same time, the viscosity of the mix is high enough to avoid phase separation between fiber and matrix. Besides, the chemical admixture also helps to disperse fibers so that the distribution of fiber is uniform and the reinforcing efficiency of fiber is enhanced.

The application of self-compacting ECC is especially beneficial in the following situations.

1. that vibration is not possible or is extremely difficult.

2. that reliability of structures is particularly important.

3. that geometry of the structure is particularly complicated.

4. construction work needs to be rationalized and cost needs to be reduced.

5. that the above conditions exist in addition to the requirement that the resulting structure or structural element exhibits high ductility, energy absorption capacity and/or high durability.

Two prototypes of self-compacting ECCs have been developed, with two different types of fibers. Test on slump cone deformability, funnel flow rate, and U-shape box obstacle self-compactibility have been carried out and confirm the self-compacting properties of this material. Additional tests on flexural specimens of the hardened self-compacting composites also confirm the super-ductility expected.