Historically, materials engineers have focused on engineering metrics, such as structural performance, efficiency, and initial cost, to drive the development of new high performance materials. However, as traditional raw materials, such as clean aggregates, sand, and limestone become scarce, the future need to focus on sustainability becomes clear.

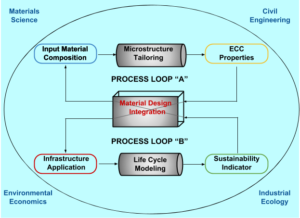

In cooperation with the University of Michigan Center for Sustainable Systems, the ACE-MRL is currently developing and refining a revolutionary design schematic incorporating material science, geology, civil engineering materials, structural engineering, transportation engineering, hydraulics engineering, social science, public policy, and life-cycle analysis to promote the design of new materials and infrastructure which incorporates sustainability considerations as a primary design concern. Working within the integrated materials design schematic, once new materials are developed, they are evaluated for traditional engineering performance, along with environmental, social, and economic metrics to determine lifetime performance and sustainability. These results are then used by materials engineers to refine the material for higher long term performance. Through this unique iterative process, new materials are introduced which are optimized for engineering performance and sustainability concerns. This methodology looks to revolutionize the way in which future materials are developed and infrastructure is designed.

A number of new versions of ECC material have been identified which substantially increase material sustainability by incorporating waste materials such as waste post-consumer carpet fiber, fly ash, waste foundry sand, and waste expanded polystyrene. These versions of ECC have been found to reduce critical material sustainability metrics, such as total carbon dioxide produced and chemically polluted water produced, by as much as 55% and 60%, respectively. Comprehensive life-cycle analysis of an ECC bridge deck system found that the ECC system had lower life-cycle costs than a conventional concrete system. The difference between the two represented a 15% cost advantage for the ECC system over a 60-year service lifetime analysis period.