(NSF Grant Number: 1068005)

Motivation

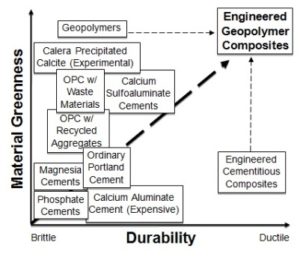

Infrastructure sustainability is a global concern today. Global cement consumption is continuously growing, and the trend seems to continue as emerging countries develop their infrastructure systems. It is known that cement production is one of the world’s most energy and carbon intensive industries, and in fact, it accounts for 5 -8 % of total man-made carbon dioxide (CO2) emissions [1]. Therefore, eco-friendly construction materials are an important key for sustainability. On the other hand, developed countries are facing the aging infrastructure problem. ASCE estimates that $3.6 trillion would be needed by 2020 for repair and maintenance of deteriorated infrastructures [2]. Another key is therefore enhanced durability for less frequent repair and longer service life. We believe that true infrastructure sustainability requires both construction material greenness and enhanced structural durability.

From the material greenness perspective, geopolymer has been drawing attention as a promising alternative to Ordinary Portland Cement (OPC). Geopolymer is a class of aluminosilicate-based cementitious materials and relies on no cement. It can be made from industrial byproducts such as fly ash, activated by alkaline solution. Geopolymer is attractive due to engineering performances such as higher strength and resistance to acid, corrosion, fire/temperature and frost [3], in addition to material greenness.

However, geopolymer is inherently brittle similar to conventional cement concrete, so that the excellent properties are often deteriorated by cracks. Cracks are almost inevitable in brittle materials, especially in large-scale field applications. It is therefore natural that geopolymer applications have been limited to niche applications or small scale products so far.

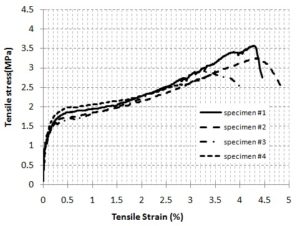

Our research group has demonstrated that fiber reinforcing can be highly effective in controlling the brittleness of cementitious materials. ECC materials have ultra-high tensile ductility of 3 – 5 %, several hundred times that of normal concrete, and the durability is greatly improved through multiple crack propagation with tightly controlled crack widths. It is considered that the micromechanics-based design developed for ECC can be applied to brittle geopolymer materials for enhancing the durability as in ECC. Therefore, it is hypothesized that combining the ECC micromechanics design basis with geopolymer matrix could lead to green and durable fiber reinforced geopolymer composites. This Engineered Geopolymer Composite (EGC) will be an entirely new material that contributes to truly sustainable infrastructure systems. This research project examines the above hypothesis theoretically and experimentally.

References

[1] K.L. Scrivener and R.J. Kirkpatrick, “Innovation in use and research on cementitious material”, Cement and Concrete Research. 38 (2008) 128-136.

[2] ASCE. www.infrastructurereportcard.org. 2013 [cited 2013 April 29, 2013].

[3] Provis, J. L., and van Deventer, J., “Geopolymers: Structures, processing, properties and industrial applications”, Cambridge (UK): Woodhead Publishing, 2009.

Goal & Approach

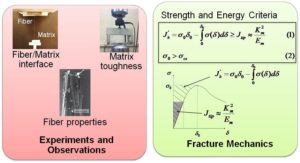

The primary goal of this project is to develop an entirely new family of truly sustainable fiber-reinforced geopolymer composites and characterize the engineering properties. Another, but significant expected achievement is the development of a powerful new design methodology to systematically produce high performance fiber reinforced composites. Based on the micromechanics-based design, fiber properties and fiber/matrix interface can be optimized for a given matrix. However, geopolymer matrices are expected to have larger properties variation than cement matrices since the source material for geopolymer (i.e. fly ash or slag) is an industrial byproduct in which quality control is not intended. Despite this, it is necessary to produce consistent geopolymer matrices. Therefore, matrix design as well as composite design should be integrated in the new design methodology. In addition, it is desired that the material greenness perspective can be also reflected in the design process.

Approach

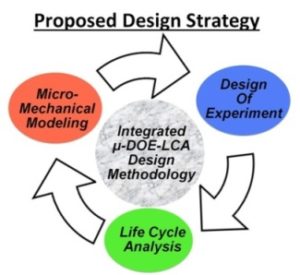

The proposed project integrates micromechanical modeling, Design of Experiment (DOE), and Life Cycle Analysis (LCA) techniques to develop a novel design methodology.

Micromechanical modeling is a powerful tool developed at the ACE-MRL to efficiently design ECC materials. This technique is based on fracture mechanics theories and carefully designed experiments to identify the optimal fiber properties and fiber/matrix interface for a given matrix. The micromechanical design methodology has enabled rapid development of a variety of ECC products, including self-compacting, lightweight, sprayable, and high early strength ECCs.

Design of Experiment is a statistical design methodology to increase the efficiency of experiments. The primary purpose is to obtain robust data from much less experimental runs on a fraction of every combination of variables. For geopolymer matrix development where numerous variables are likely to be considered, the DOE technique can be helpful to design efficient experimental combinations. While DOE has been utilized in various fields of science and engineering, the application in geopolymer research has so far been limited.

Both micromechanical modeling and DOE are used for gaining higher mechanical performances of composites. To quantify ecological properties of developed materials for actual field applications, LCA must be used. LCA employs environmental, social, and economic metrics to account for input and output factors at all life-cycle phases, from materials processing to infrastructure usage and maintenance, to end-of-life management. True sustainability of durable geopolymer composites is properly evaluated when the expected longer service life due to enhanced durability is taken into account in LCA, as well as the material greenness.

The integration of micromechanical modeling, DOE, and LCA into a novel synergistic design methodology (μ-DOE-LCA) enables the systematic development of truly sustainable EGC materials. This synergistic methodology will be useful not only in the field of sustainable construction materials development, but will be adaptable to composite materials development for other industrial sectors.

Results so far

It has been experimentally demonstrated that fiber reinforced fly ash-based geopolymer can exhibit tensile strain-hardening behavior with ultra-high ductility of more than 4 %. The tensile ductility is about 400 times that of normal concrete and multiple crack propagation with tiny crack widths is also observed as in ECC materials. Further improvement in mechanical properties and controlling variability due to fly ash is the next step.